Sprockets, Gear, and Racks are Essential Mechanical Components Widely used in Various Machines and Systems to Transmit Motion and Power Efficiently.

Sprockets

Sprockets are Toothed Wheels that Engage with a Chain or Belt to Transmit Rotational Motion. They are Commonly Found in Bicycles, Motorcycles, and Industrial Machinery. the Key Characteristics of Sprockets Include:

- Tooth Design: The Shape and Size of the Teeth affect the Efficiency and Smoothness of Power Transfer.

- Material: Sprockets are Typically made from Steel, Aluminium, or Plastic, Depending on their Intended Application.

Gears

Gear are Rotating Machine Parts with Teeth that Mesh with One Another to Transmit Torque and Rotational Motion. They Come in Various Types, Including Spur Gear, Bevel Gear, and Worm Gear. The Critical Features of Gear Include:

- Gear Ratio: The Ratio Between the Number of Teeth on Two Meshing Gear Determines the Mechanical Advantage and Speed of Operation.

- Types of Gear: Each Type has Specific Applications Based on the Direction of Force and Speed Required.

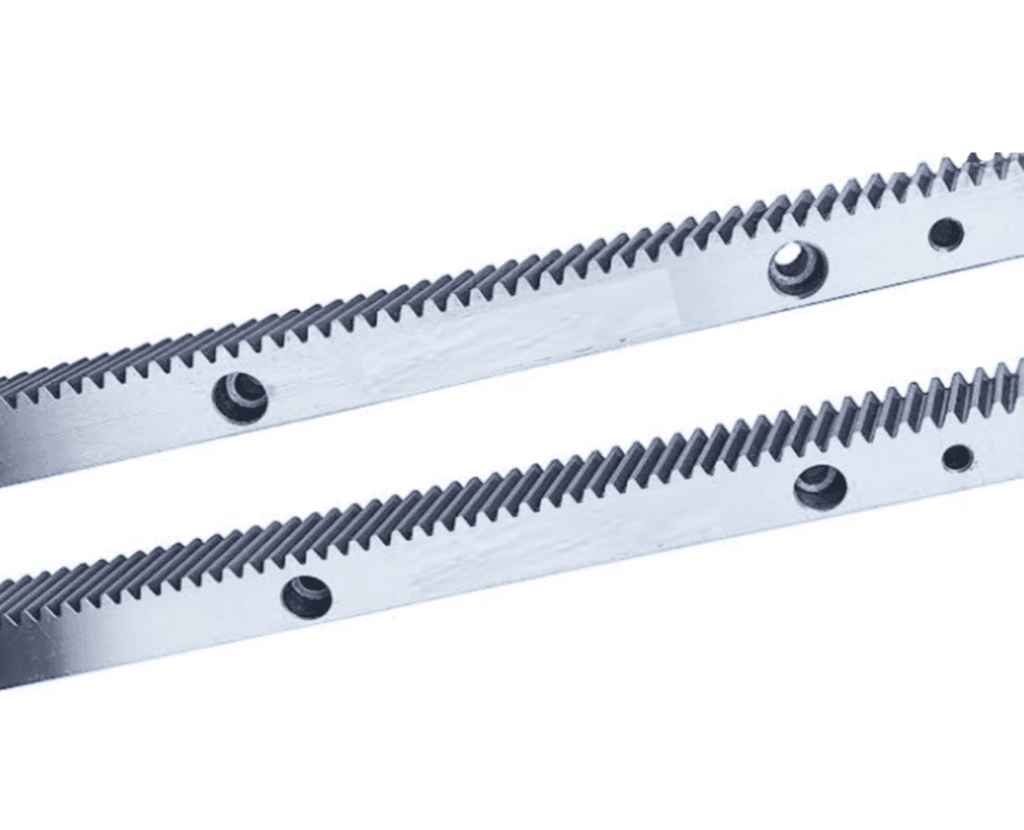

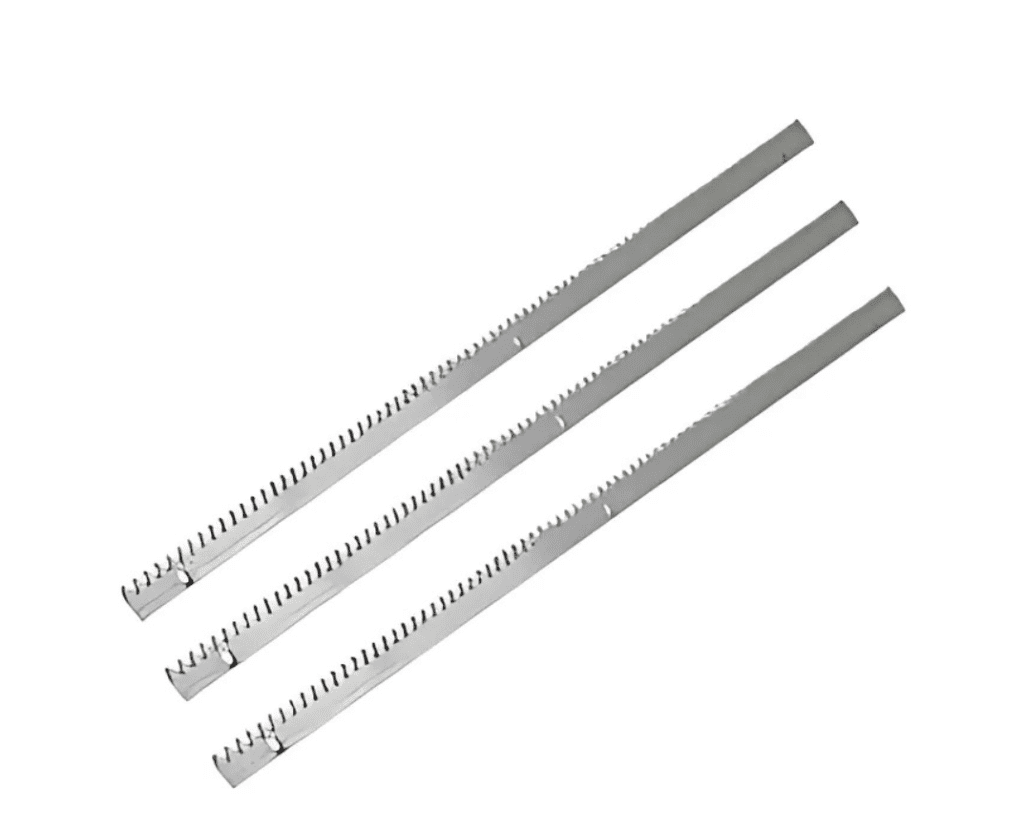

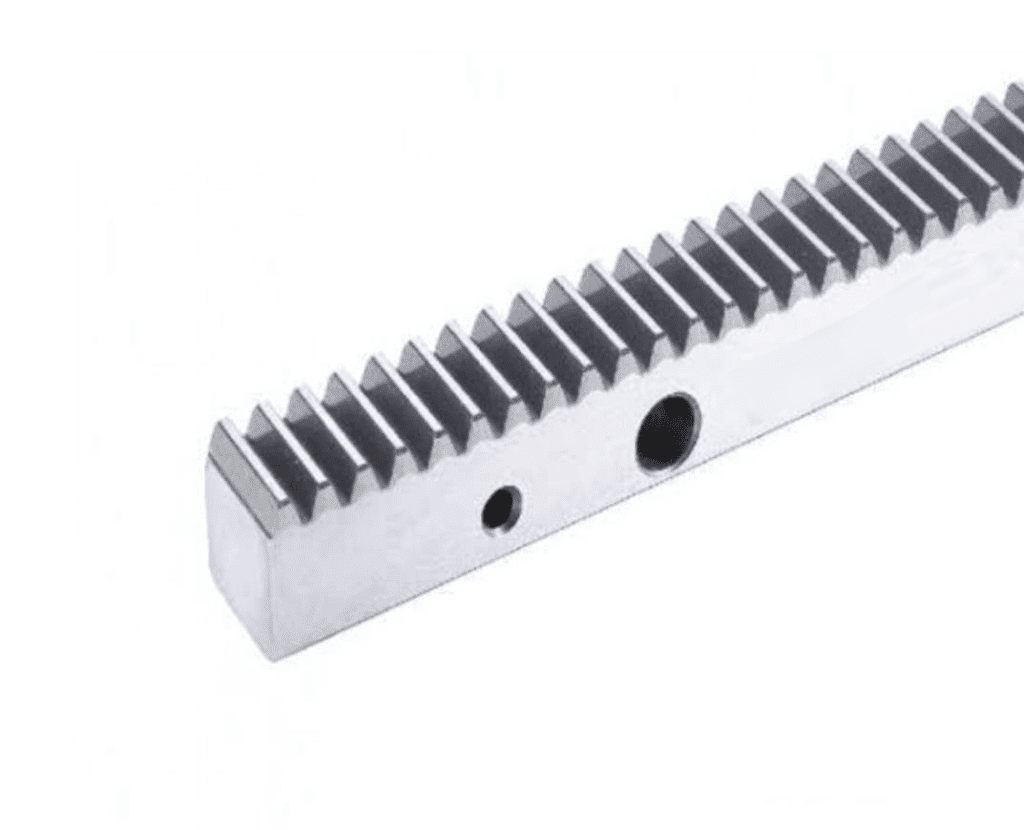

Racks

Racks are Linear Mechanical Components with Teeth that Engage with Pinions (Small Gear) to Convert Rotational Motion into Linear Motion. They are Used in Applications Such as Steering Systems and Linear Actuators. Key Aspects of Racks Include:

- Tooth Profile: The Shape and Size of the Teeth are Designed to Ensure Smooth Engagement with Pinions.

- Length and Width: Racks Come in Various Sizes to Accommodate Different Applications and Load Requirements.

Applications and Need

- Automotive Industry: Sprockets and Gear are Crucial in Engines, Transmissions, and Steering Systems, Enhancing Efficiency and Performance.

- Industrial Machinery: These Components are Used in Conveyor Systems, Robotics, and Manufacturing Equipment for Precise Movement and Control.

- Bicycles and Motorcycles: Sprockets are Essential for Power Transfer from the Pedals or Engine to the Wheels, Ensuring Smooth Operation.

- Material Handling: Racks and Pinion Systems are Used in Lift Systems and Forklifts for Lifting and Moving Heavy Loads.

- Aerospace and Defense: Sprockets and Gear Play a Critical Role in Flight Control Systems, Providing Reliable Performance Under Extreme Conditions.

Sprocket, Gear, Rack Manufacturer

Finding a Reliable Sprockets, Gear, and Racks Manufacturer is Crucial for Ensuring High-Quality Components that Meet Specific Application Needs. When Selecting a Manufacturer, Consider the Following:

- Quality Standards: Look for Manufacturers that Adhere to Industry Standards for Quality and Performance.

- Customization: Choose a Manufacturer that Can Provide Tailored Solutions to Meet Your Unique Requirements.

- Experience: An Established Manufacturer with a Proven Track Record Can Offer Valuable Expertise and Support.

In Conclusion, Sprockets, Gear, and Racks are Vital Components in Numerous Applications, Driving the Efficiency and Functionality of Various Systems. Partnering with a Reputable Manufacturer Ensures you Receive High-Quality, Reliable Products Tailored to Your Specific Needs.