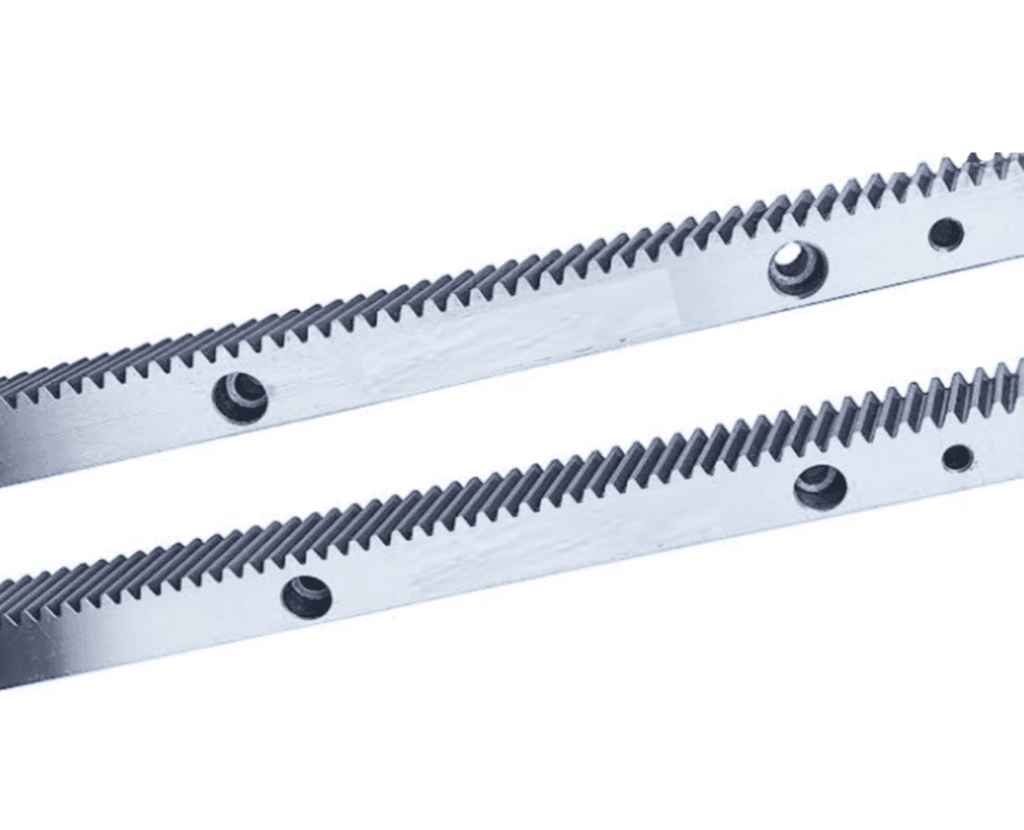

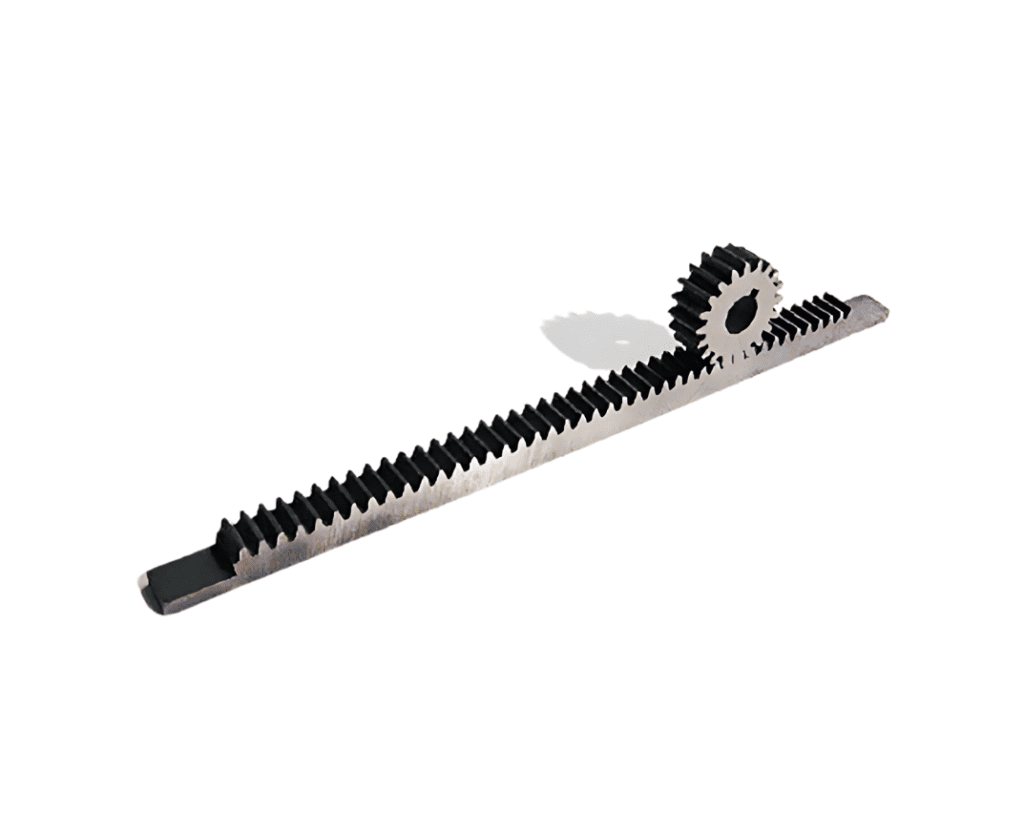

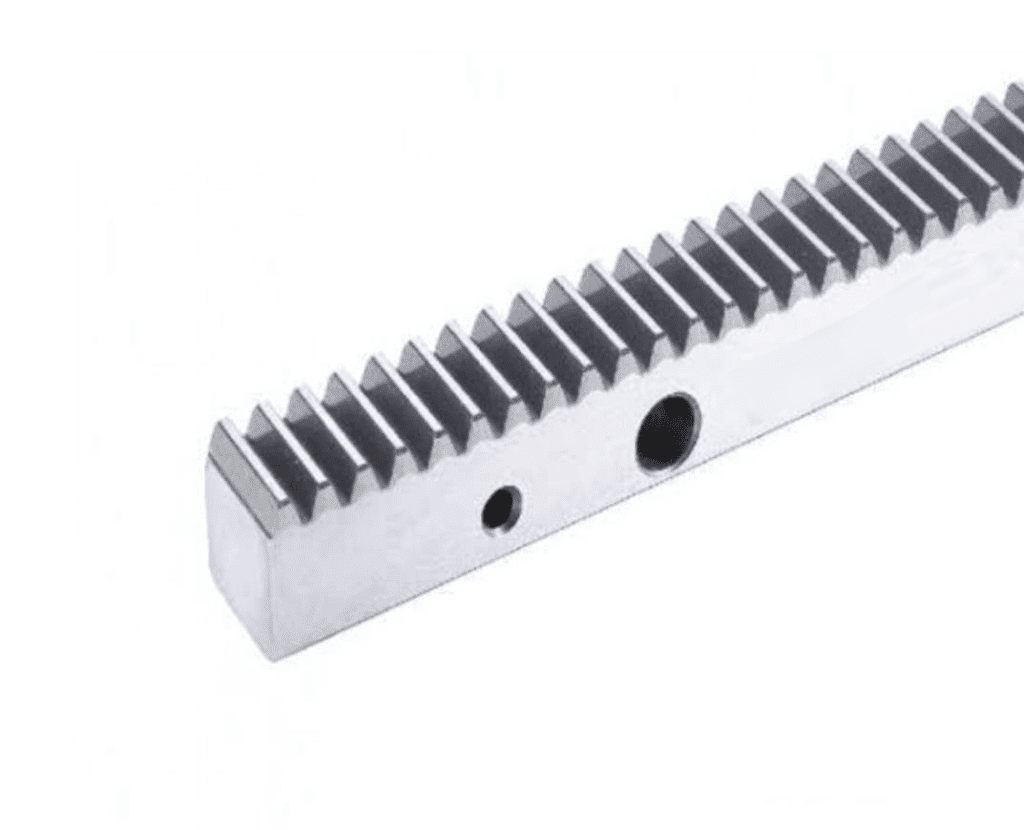

Precision Gear Racks are Mechanical Components Designed to Work in Tandem with Gear, Providing Linear Motion from Rotary Motion. They Consist of a Straight, Toothed Bar that Engages with a Gear (also called a Pinion) to Convert Rotational Movement into Linear Motion or Vice Versa. Precision Gear Racks are Engineered with High Accuracy, Ensuring Smooth and Reliable Motion Control in Various Industrial Applications.

Key Features of Precision Gear Rack

- High Accuracy: Manufactured to Meet Tight Tolerances, Ensuring Precise Motion Control.

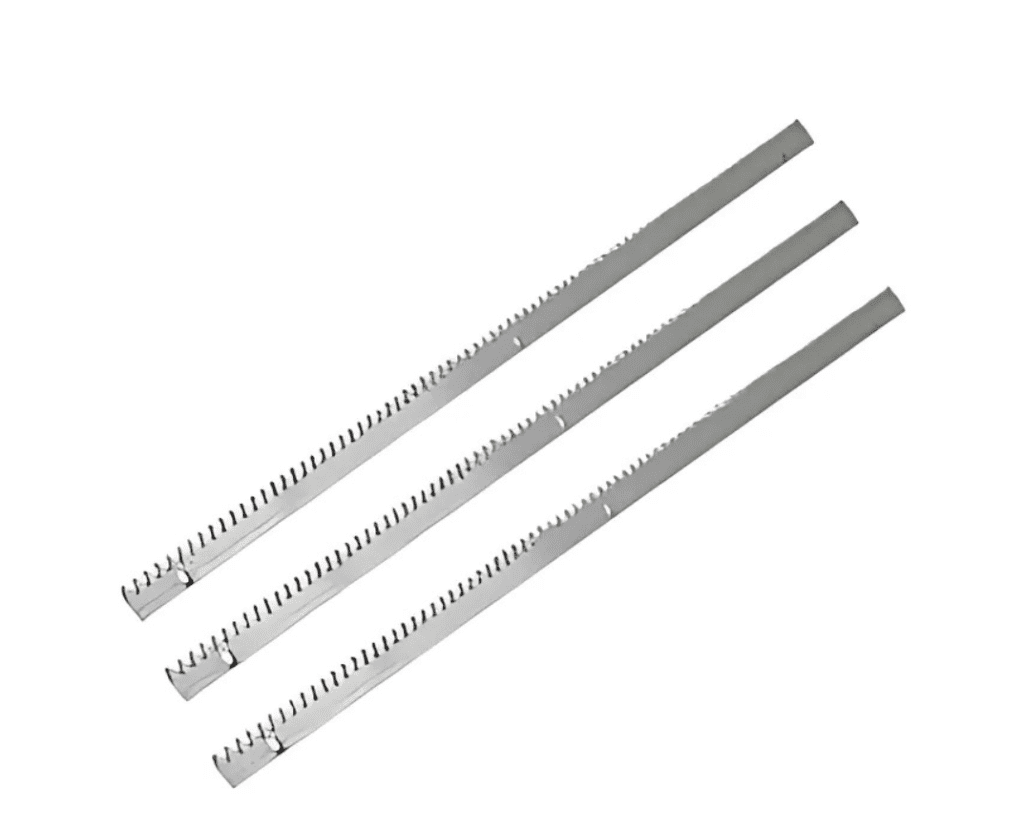

- Durability:Made from High-Strength Materials that can Withstand Wear and Tear Over Extended Periods.

- Low Noise Operation: Designed to Minimize Noise and Vibration During Operation, Making them Suitable for Environments Requiring Quiet Performance.

- Customizable: Available in Different Lengths, Pitches, and Materials to Meet Specific Application Needs.

Applications of Precision Gear Rack

Precision gear racks are specially designed to provide accurate linear motion with minimal backlash and high rigidity. They are manufactured to tight tolerances, making them suitable for various high-performance applications. Here are some common applications:

- CNC Machines: Used to Move the Cutting Tool or Workpiece Accurately, Ensuring Precise Machining Operations.

- Robotics: Applied in Robotic Arms and Automated Systems for Accurate Positioning and Smooth Motion Control.

- 3D Printers: Essential for the Precise Movement of Print Heads and Build Platforms, Allowing for High-Quality Printing.

- Automation and Conveying Systems: Utilized in Conveyors and Automated Assembly Lines for Reliable, Repeatable Linear Movement.

- Medical Equipment: Found in Devices Such as Surgical Robots and Imaging Systems, Where Precision and Reliability are Critical.

- Industrial Machinery: Used in Machinery that Requires Precise Alignment and Movement, Such as Presses and Cutting Machines.

- Optical Equipment: Employed in Laser Cutting Systems and Optical Positioning Devices for Accurate Alignment and Focus Adjustments.

- Measurement Instruments: Applied in Linear Measuring Devices, Where Precision is Essential for Accurate Data Collection and Analysis.