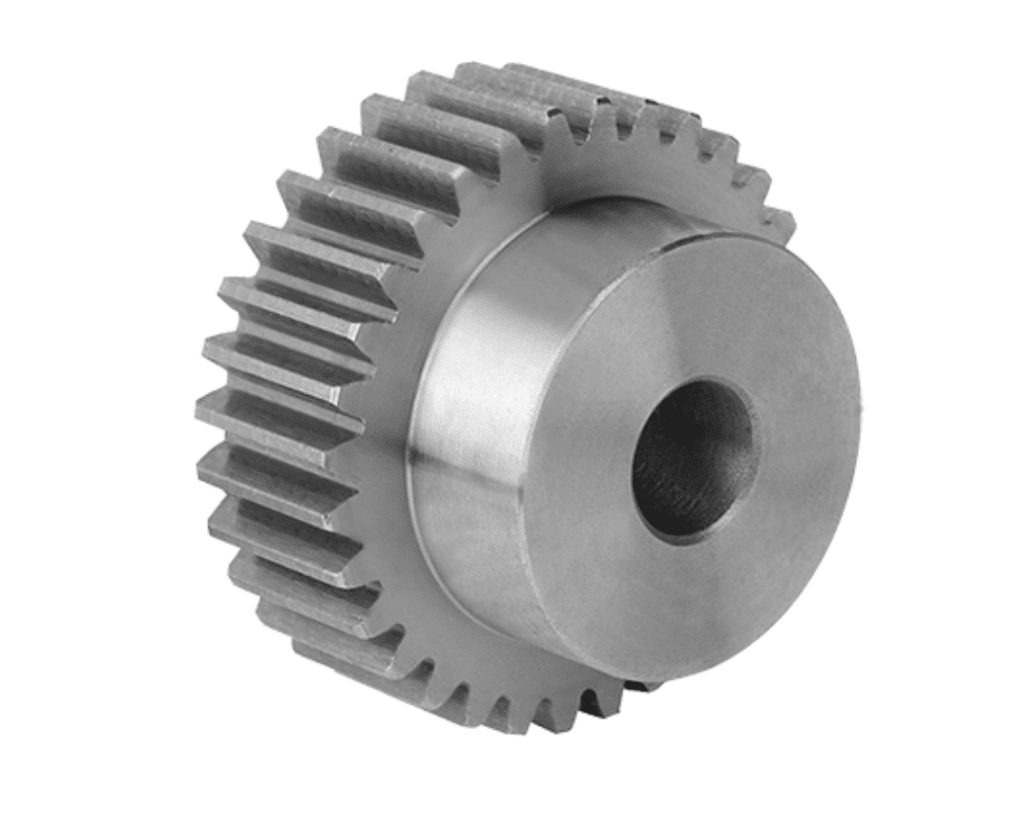

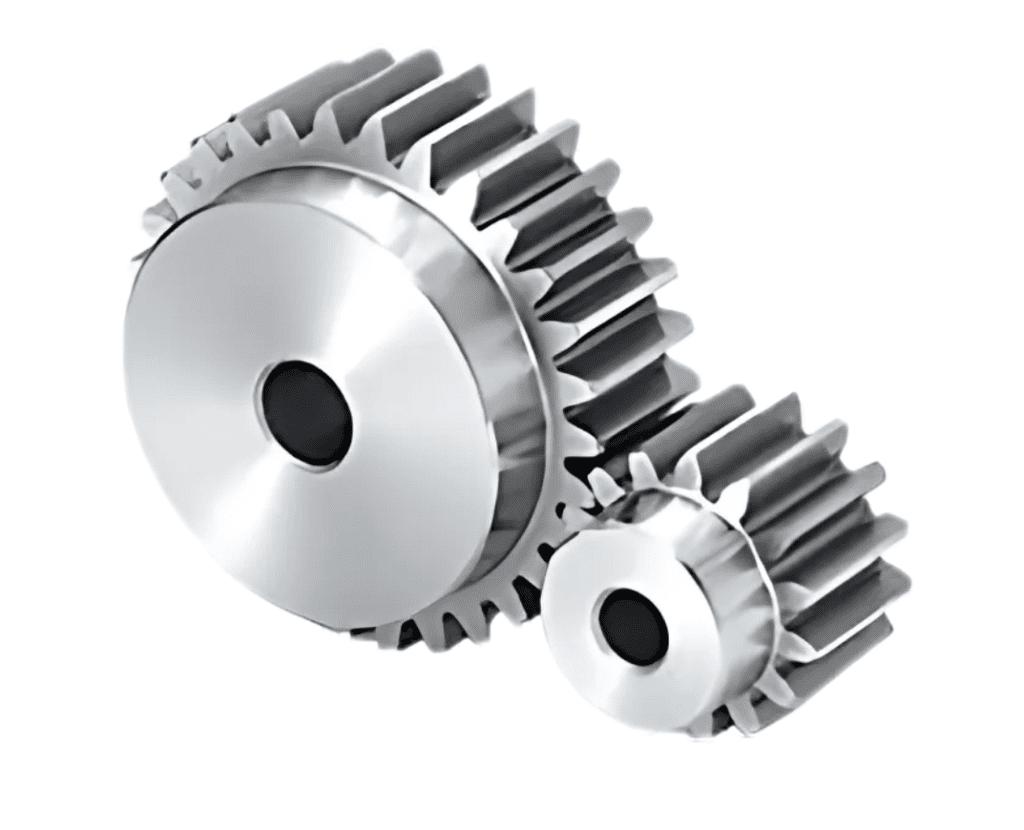

Spur gear is the most common type of gear used in machinery. These gear have straight teeth and are mounted on parallel shafts. The teeth engage in such a way that the motion is transferred smoothly, making them efficient for transmitting power between two rotating shafts. Spur Gear is known for its simplicity in design, ease of manufacturing, and reliability in various industrial applications

Industries that Frequently Need Spur Gears:

Spur gear is widely used in industries due to its straightforward design and efficiency. Here are some key applications:

Automotive Industry

- Spur Gear transmits power from the engine to the wheels.

- Used in manual transmissions, automatic transmissions, differential Gear, and other drivetrain components.

Industrial Machinery

- Found in gearboxes, conveyor systems, pumps, compressors, and machine tools.

- Ensure smooth torque transmission and rotational movement essential for manufacturing.

- Heavy Loaded Reduction Gear provides reliable torque transmission in demanding industrial applications.

Aerospace and Aviation

- Used in aircraft engines, landing gear mechanisms, and flight control systems.

- Ensure smooth and safe operation with high reliability and efficiency.

Power Generation

- Integral in wind turbines, hydroelectric turbines, and steam turbines.

- Convert rotational movement into electrical energy by driving generators.

Textile Industry

- Used in spinning, weaving, and dyeing machinery.

- Ensure precise control and smooth movement of machine components.

Printing, Packaging, and Consumer Products

- Drive rollers, conveyors, and other moving parts in printing and packaging equipment.

- Found in products like clocks, watches, printers, copiers, and power tools for accurate motion control.