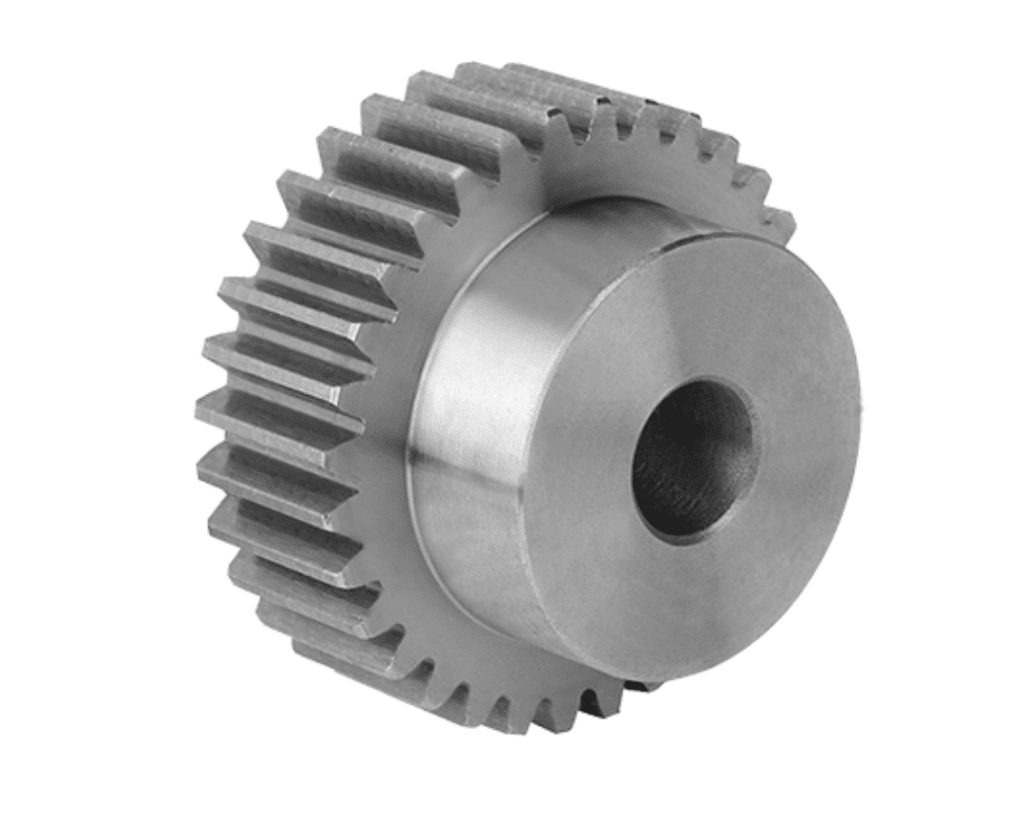

Screw Gears, also known as crossed helical Gears, are a type of mechanical gear used to transmit motion between two non-parallel, non-intersecting shafts. Unlike traditional Gear, which usually meshes on parallel or intersecting axes, screw Gear has its axes placed at an angle. These Gear are usually designed with helical teeth that are set at an angle, allowing them to mesh smoothly even at non-parallel angles. They operate similarly to Worm Gear but have a lower ratio.

Applications of Screw Gears

- Textile Machinery: Helps control the movement of rollers and spindles in spinning and weaving machines.

- Printing Presses: Used to drive components that operate at skew angles, ensuring smooth operation without slipping.

- Conveyor Systems: Facilitates movement between skewed shafts for material handling in factory setups.

- Measuring Equipment: Applied in devices like protractors or measuring wheels, where slow-speed, smooth motion is needed.

- Industrial Mixers: Transfers power between non-parallel shafts to mix or stir components.

- Hand Tools: Used in some hand drills for torque transmission between angled components.

- Automated Systems and Robotics: Helps drive parts that need to operate at slight angles concerning each other, reducing alignment issues.

Benefits of Screw Gears

- Smooth Operation: Due to the helical design, screw Gear provides smoother and quieter operation compared to traditional spur Gear.

- Compact Design: Ideal for systems where space is limited, as screw Gear can transmit power over angled axes.

- High Efficiency: Despite their complex geometry, screw Gear maintain high efficiency in power transmission.