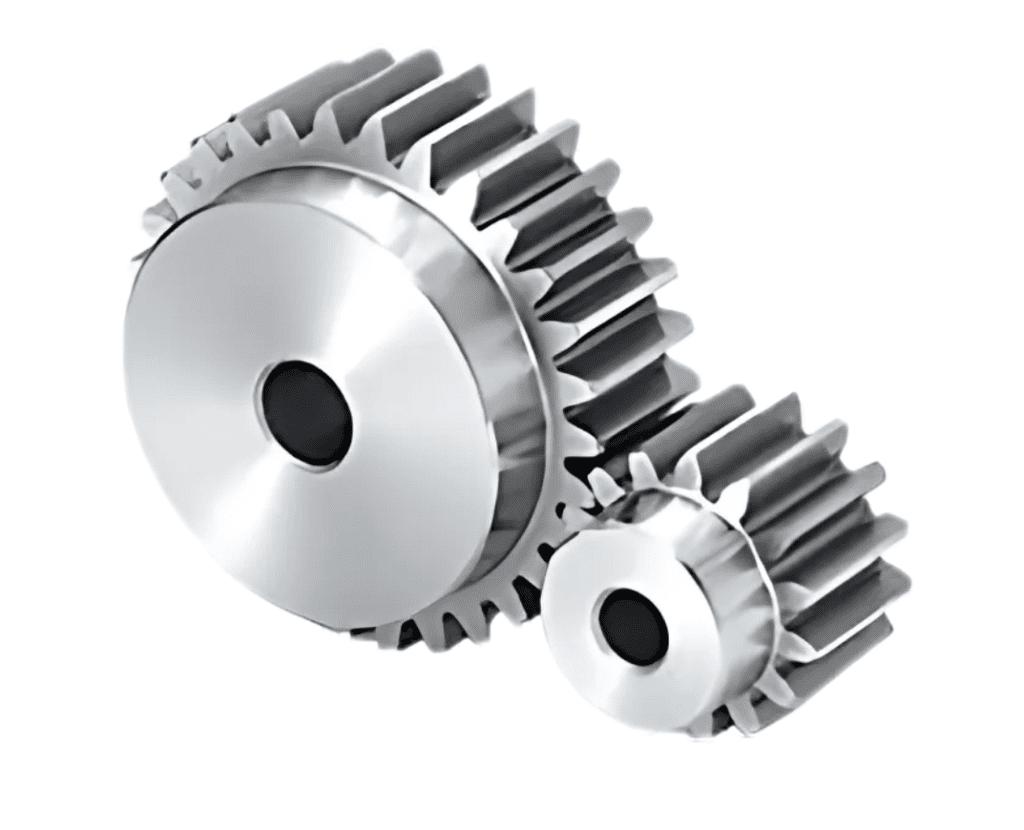

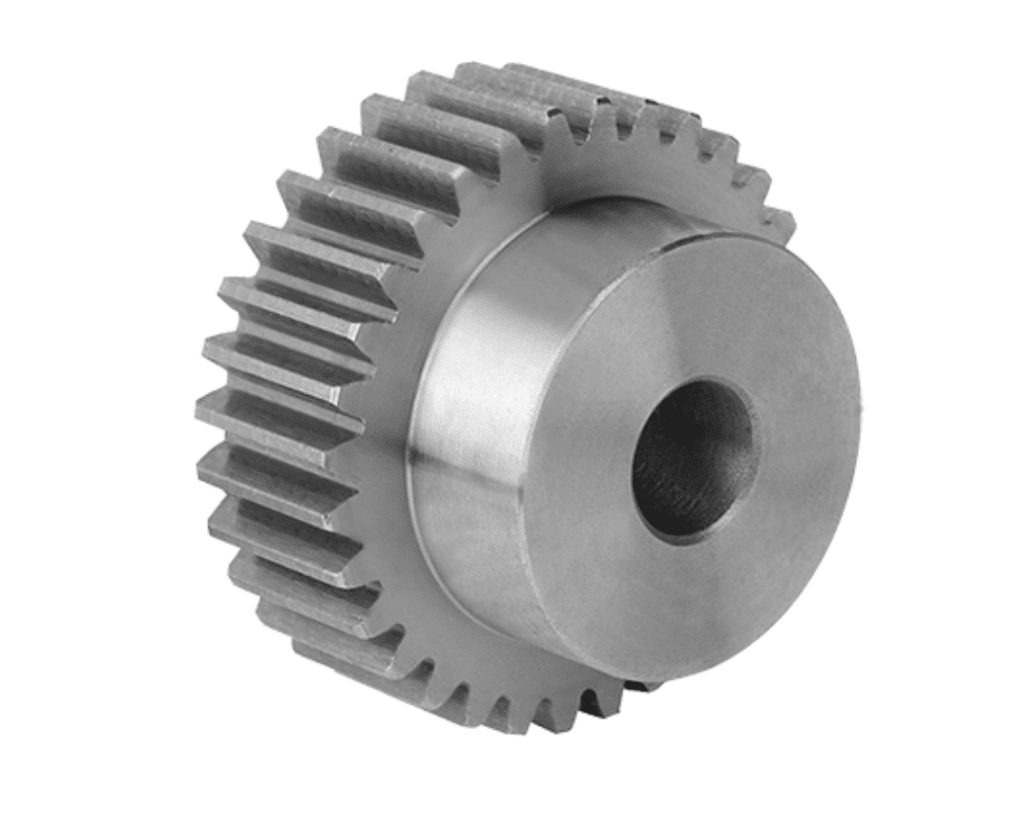

The Metric Spur Gear module is a key parameter used to define the size and geometry of the spur Gear. It represents the ratio of the pitch diameter to the number of teeth, serving as a universal standard in metric systems. This module allows manufacturers to design and produce Gear with consistent dimensions and compatibility, ensuring smooth engagement and efficient power transmission. In simpler terms, the metric spur gear module dictates the size and spacing of the teeth on the gear, helping engineers select the correct gear for their machinery.

Application Need for Metric Spur Gear Module

- Precision in Design: The module ensures the precise sizing of Gear, critical in mechanical systems where accuracy is key to function.

- Standardization: Metric spur Gear provides a universal standard for manufacturers and industries worldwide, making it easy to replace or interchange parts.

- Smooth Power Transmission: Properly designed Gear using the right module can help achieve efficient power transmission, minimizing noise and wear.

- Mechanical Efficiency: These Gears are essential for ensuring the mechanical efficiency of machines, and optimizing torque and speed.

- Versatility: Metric spur Gear is used in a wide variety of applications, including automotive, industrial machinery, robotics, and conveyor systems.

- Cost-Effectiveness: By using standardized Gear, manufacturers can produce and supply components at a lower cost, reducing expenses for machine builders.

Metric Spur Gear Module Manufacturer

Choosing the right Metric Spur Gear module manufacturer is crucial for ensuring high-quality performance and durability. Manufacturers with expertise in precision engineering can deliver Gear that meets industry standards, enhancing the reliability and lifespan of mechanical systems.