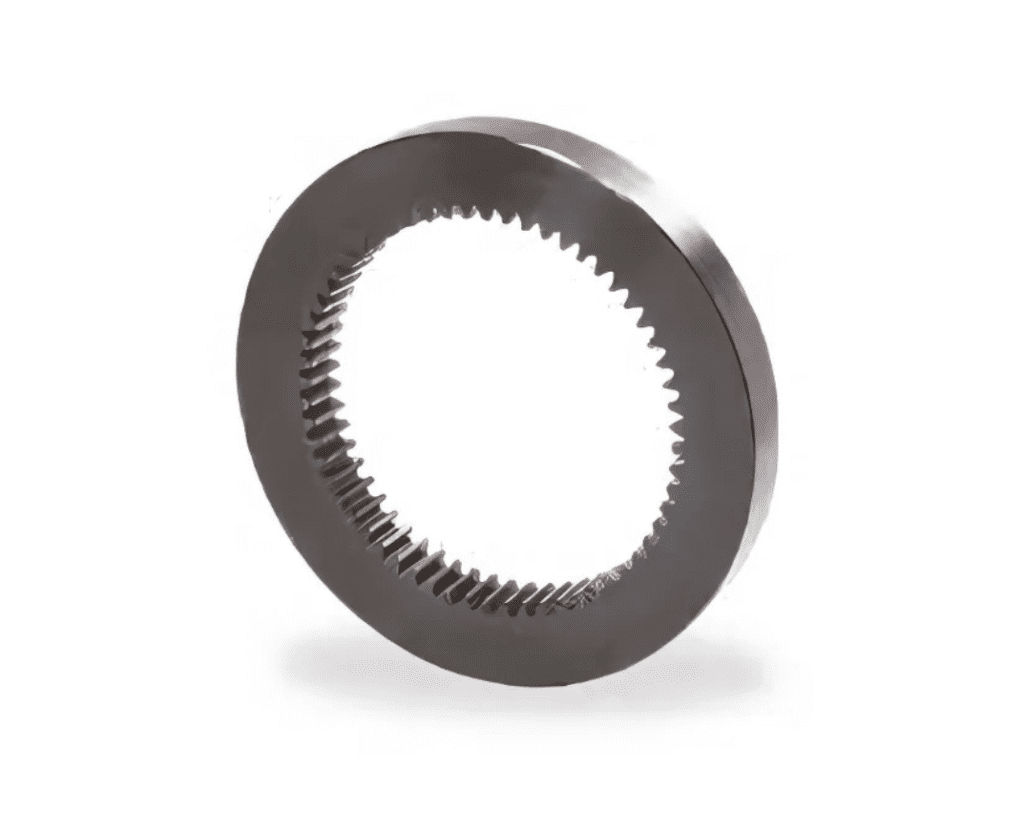

Internal Gear, also known as ring Gear, is a type of gear where the teeth are cut on the inner surface of a cylindrical or conical shape. Unlike external Gear, where the teeth are on the outer surface, internal Gear mesh with external Gear to transfer power in a more compact design. These Gear are often used in systems where space is limited, allowing for efficient power transmission within a confined area.

Internal Gears is commonly used in planetary gear systems, where it works in conjunction with the sun gear and planet Gear to achieve high torque and smooth operation. It can be found in a wide range of applications, including automotive transmissions, industrial machinery, and robotics.

Applications of Internal Gear

Internal Gear are Gear with teeth on the inside surface of a cylindrical or conical shape. They mesh with external Gear and are widely used for compact power transmission. Here are some common applications:

- Planetary Gear Systems: Found in automatic transmissions, robotics, and wind turbines for speed reduction and torque multiplication.

- Hydraulic Motors and Pumps: Internal Gear ensures smooth fluid flow, minimizing pressure pulsations.

- Watches and Clocks: Used in miniature gear trains for precise movement and compact design.

- Electric Vehicles (EVs): Incorporated into powertrains for efficient torque distribution.

- Conveyor Systems: Applied in gear-driven rollers for material handling.

- Mixers and Agitators: Utilized in industrial machines to ensure smooth, quiet, and efficient operation.

- Robotics and Automation: Used for compact and precise actuation mechanisms within robotic joints.

Internal Gears is ideal for applications requiring compactness, smooth operation, and low backlash, especially where high torque transmission is essential in limited space.