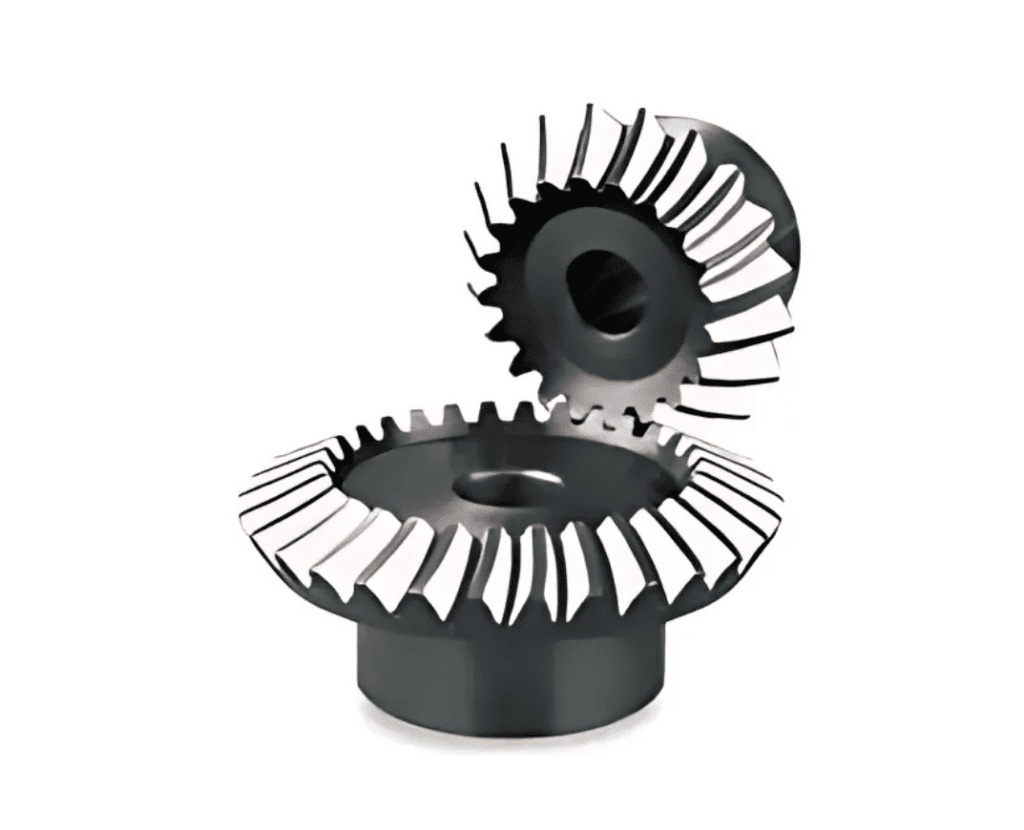

Bevel gear are a type of gear that allows the transfer of motion between intersecting shafts, typically at a 90-degree angle. They have conically shaped teeth, and their design enables smooth, efficient transmission of power and torque between shafts at different orientations. Bevel Gear come in different types, such as straight bevel gear, spiral bevel Gear, and hypoid Gear, each suited for specific applications and load requirements.

Applications of Bevel Gear

Aerospace

- High-speed straight and spiral bevel Gear for jet applications (up to 16,000 rpm).

- Made with special steel and processes for enhanced durability.

Air Pre-heater

- Straight bevel Gear for pre-heater gearboxes.

Cement Mills

- Lapped and hard-cut gear options are available.

- Reverse engineering services are offered.

Cone Crushers & Sand Mixers

- Engineering design assistance was provided.

- Available options: straight, spiral, or skew bevel Gear.

- Hard-cut Gear for improved strength.

Cooling Tower

- Ground and lapped Gear for cooling tower applications.

- Ground teeth ensure smooth operation, reduced noise, and lower vibration.

Defense

- Special material grades for high power density applications.

- Legacy products are supported

Fork Lift

- Lapped and ground gear options.

- Various brands and gear ratios are available.

Live Tooling

- Lapped or ground gear options for high-rpm applications.

Marine

- Gear solutions for stern drives and thrusters.

Mining

- Gear systems for:

- Bucket wheel excavators

- Stacker/reclaimer drives

- Dredger drives

- Mill drives

- Belt conveyors

Packaging & Food Processing

- Gearboxes designed for:

- Pharmaceutical packaging machines

- Can production equipment

- Polythene foil production

Printing

- High-speed Gear for offset printing.

Railways

- Registered supplier to Indian Railways.

- Expertise in overhauling and rebuilding projects.

- Reverse engineering for diesel locomotive final and secondary drives.

Rallying, Racing, and Vintage & Classic Cars

- Reverse engineering options for material upgrades and ratio changes.

- Spiral bevel grinding for performance improvements.

Robotics

- Angular bevel Gear is designed for compact spaces.

- Straight and spiral bevel gear options available.

Steel

- Parallel depth tooth options.

- Gear for vertical rolling mill stands and angular sizing mills.