Gear Racks for Laser Cutting Machine

Our Industries

- Hydraulic Industry

- Automotive Industry

- Pneumatic Industry

- Steel Industry

- Construction Industry

- Sheet Bending Industry

- Oil & Gas Industry

- Drill Machine

- Robotics

- Power Plants

- Plasma Cutting Machine

- Aerospace

- Defense

- Industrial Machinery

- Renewable Energy

- Railroad Equipment Manufacturing

- Electrical Industry

- Automation Industry

- Material Handling Industry

- Laser Cutting Machine Manufacturers

- Wood Cutting Machines

- CNC Machine Tools

Enquire Now

Gear Racks for Laser Cutting Machine

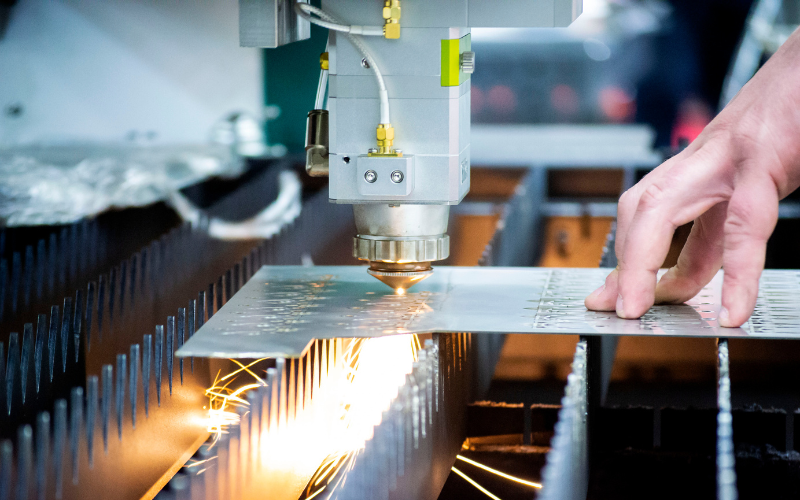

At Kreymayer, we offer state-of-the-art laser cutting machines designed for high precision, speed, and versatility across industries. Whether you’re in manufacturing, automotive, aerospace, or custom fabrication, our laser cutting machines provide the precision and efficiency needed to transform your operations. Crafted with robust technology and innovative design, our laser cutting systems are built to handle intricate designs, complex materials, and high-volume production with ease.

Our Laser Cutting Machines

- Exceptional Precision for Intricate Designs

Utilizing advanced laser technology, our machines deliver highly precise cuts down to the smallest detail. This precision is ideal for industries requiring complex shapes and patterns, offering cutting tolerances as tight as 0.01 mm for consistent, reliable results. - Speed and Efficiency for High-Volume Production

Designed to meet demanding production schedules, our laser cutting machines offer high-speed performance without compromising accuracy. This efficiency allows you to reduce cycle times and increase output, helping you stay ahead of deadlines and maximize productivity. - Versatility Across Materials

From metals and alloys to plastics, wood, and textiles, our laser cutting machines can process a wide variety of materials. Adjustable power settings and customizable parameters allow for optimal performance across different materials and thicknesses, making our machines a versatile solution for diverse industries. - User-Friendly Interface and Automation Options

Our machines feature intuitive control panels and advanced software that allow for easy setup and operation. With automation options like robotic loading/unloading, your team can operate more efficiently, reducing manual intervention and minimizing downtime.

Features of Our Gear Racks and Pinions for Laser Cutting Machine

High-Power Laser Sources

Choose from a range of fiber and CO2 laser sources that offer powerful, focused energy for precise cutting on both thin and thick materials. Our lasers are designed for minimal maintenance and extended lifespan, ensuring reliable performance for years to come.

Precision Motion Control Systems

Our laser cutting machines are equipped with high-precision motion control systems that guide the laser with exceptional accuracy. This technology supports both intricate designs and fast cutting speeds, delivering consistent quality every time.

Efficient Cooling Systems

Advanced cooling mechanisms ensure that the machine remains at optimal temperature, even during intensive production runs. This feature enhances machine longevity, reduces wear on components, and keeps maintenance requirements low.

Real-Time Monitoring and Diagnostics

Integrated sensors and software offer real-time monitoring and diagnostics, enabling you to track performance metrics, monitor power output, and detect any irregularities. This helps reduce downtime and supports predictive maintenance for maximum operational efficiency.

Benefiting from Our Gear Racks for Laser Cutting Machine

Our laser cutting technology has proven invaluable across multiple sectors, providing a competitive edge in product quality, cost savings, and efficiency. Key industries that benefit include:

- Automotive: Fabrication of metal components, custom parts, and intricate detailing.

- Aerospace: Precision cutting for lightweight metals and alloys used in aircraft manufacturing.

- Electronics: Micron-level precision for delicate components and circuits.

- Signage & Display: Customizable cutting for signage materials, creating crisp, detailed finishes.

- Jewelry & Fashion: Fine detailing on metals and textiles for high-end products.

Customized Solutions for Unique Gear Racks and Pinions for Laser Cutting Machine Applications

1. X and Y-Axis Movement

- Cutting Head Movement: In laser cutting machines, the cutting head typically moves along both the X and Y axes to follow the design path of the material being cut. Gear racks are used to provide precise linear movement of the cutting head along these axes. The rack and pinion mechanism ensures that the head moves smoothly and accurately across the surface of the material.

- High Precision: The accuracy required for laser cutting, especially in industries like aerospace, automotive, and electronics, demands that the cutting head moves with extremely precise linear control. Gear racks ensure the cutting head moves along exact coordinates without deviation

2. Worktable Movement

- Material Positioning: Gear racks are also used to control the movement of the worktable, which holds the material during the cutting process. The table may need to move to different positions or be indexed automatically to adjust the cutting area. Gear racks ensure that the table moves with accuracy, allowing the laser to cut the material as required.

- Load Handling: In industrial laser cutting machines, the worktable can hold large, heavy sheets of metal or other materials. Gear racks are robust enough to support the weight of the table and material, ensuring smooth, controlled movement even under heavy loads.

3. Z-Axis Movement

- Focus Adjustment: The Z-axis in laser cutting machines controls the vertical movement of the laser cutting head, adjusting its focus distance from the material. Gear racks are used to provide precise control of this vertical movement, ensuring that the laser maintains an optimal focal distance for accurate cutting.

- Auto-Focus Systems: In some advanced laser cutting machines, gear racks are part of the autofocus system that automatically adjusts the cutting head’s position to compensate for material thickness or surface irregularities. This ensures the laser stays focused on the work surface at all times.

4. Laser Beam Path Alignment

- Alignment Adjustment: Gear racks can also assist in adjusting the alignment of the laser beam. In some machines, the laser head is mounted on adjustable rails, and gear racks are used to move the laser head along these rails to align the beam properly with the material. This ensures the laser remains on the correct cutting path during the operation.

- Beam Adjustment Mechanism: For some cutting machines, gear racks may also be used to adjust the beam’s angle or direction for more complex cutting tasks, allowing for angular cuts or beveling.

5. Cutting Table Loading and Unloading Systems

- Automated Material Handling: Gear racks are used in automated systems that load and unload materials on the cutting table. In many modern laser cutting machines, the process of placing the material on the table and removing finished pieces is automated to increase efficiency. Gear racks drive these automated systems, ensuring the material is correctly positioned for cutting and that finished parts are moved to the appropriate location after the cut.

- Precision Handling: Gear racks provide the necessary motion to move materials with high precision, ensuring that even thin or fragile sheets of material are handled gently and positioned correctly without distortion.

6. Laser Cutter Frame and Gantry Systems

- Gantry Design Movement: Many laser cutting machines use a gantry-style frame, where the cutting head moves along the gantry rail, which is supported by gear racks. This system provides a stable and rigid structure that minimizes any vibration or misalignment during cutting. The rack and pinion mechanism ensures that the gantry moves smoothly and precisely along the X, Y, and sometimes Z axes.

- Heavy Duty Loads: Gear racks are well-suited to the high-load requirements of gantry systems, as they can handle the weight of the laser cutting head and any additional support structures without compromising performance.

7. High-Speed Motion Control

- Increased Cutting Speed: Modern laser cutting machines operate at high speeds, cutting materials at fast rates to improve productivity. Gear racks are used in these systems because they allow for high-speed, precise motion control, which is essential when cutting intricate patterns or when working with large sheets of material.

- Low Maintenance: Gear racks are designed to handle high-speed operation with minimal wear and tear, making them ideal for high-performance laser cutting machines that run continuously.

8. Laser Cutting Machine Calibration

- Position Calibration: Gear racks can assist in the calibration process of laser cutting machines, ensuring that the cutting head or table is positioned correctly relative to the laser beam. This is important for ensuring accurate and consistent cuts across multiple jobs.

- Precision Cutting: Accurate calibration of the machine’s motion system, powered by gear racks, is necessary for producing high-quality cuts, especially when working with materials like metals, plastics, and ceramics.

9. Laser Cutter Maintenance

- Ease of Adjustment: Gear racks make it easier to adjust the position of the cutting head and worktable during maintenance. This allows technicians to troubleshoot, clean, or replace components in the motion system while ensuring that the machine’s alignment is restored accurately.

- Consistency in Performance: Proper alignment and maintenance of the gear rack and pinion system are essential for maintaining the cutting accuracy and quality of the laser cutting machine, ensuring consistent performance over time.

Ready to Revolutionize Your Production with a Laser Cutting Machine

Take your business to the next level with Kreymayer’s Gear Racks and Pinions for Laser Cutting Machine. Our experts are here to help you find the perfect machine for your needs or design a custom solution that meets your specifications. Contact us today to learn more about our offerings, request a demo, or speak with a member of our team to find out how we can help you improve your production efficiency and quality.

CONNECT WITH US

- Vora Industries - 91, Jawahar Industrial Estate, Kamothe Panvel 410209

- Sales: +91 7400047344

Popular Searches

Kreymayer Offers Top Quality Gear Racks and Pinions for Hydraulic Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Automotive Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Pneumatic Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Steel Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Construction Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Sheet Bending Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Oil & Gas Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Drill Machine in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Robotics in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Power Plants in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Plasma Cutting Machine in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Aerospace in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Defense in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Industrial Machinery in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Renewable Energy in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Railroad Equipment Manufacturing in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Electrical Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam