Gear Racks for CNC Machine Tools

Our Industries

- Hydraulic Industry

- Automotive Industry

- Pneumatic Industry

- Steel Industry

- Construction Industry

- Sheet Bending Industry

- Oil & Gas Industry

- Drill Machine

- Robotics

- Power Plants

- Plasma Cutting Machine

- Aerospace

- Defense

- Industrial Machinery

- Renewable Energy

- Railroad Equipment Manufacturing

- Electrical Industry

- Automation Industry

- Material Handling Industry

- Laser Cutting Machine Manufacturers

- Wood Cutting Machines

- CNC Machine Tools

Enquire Now

Gear Racks for CNC Machine Tools

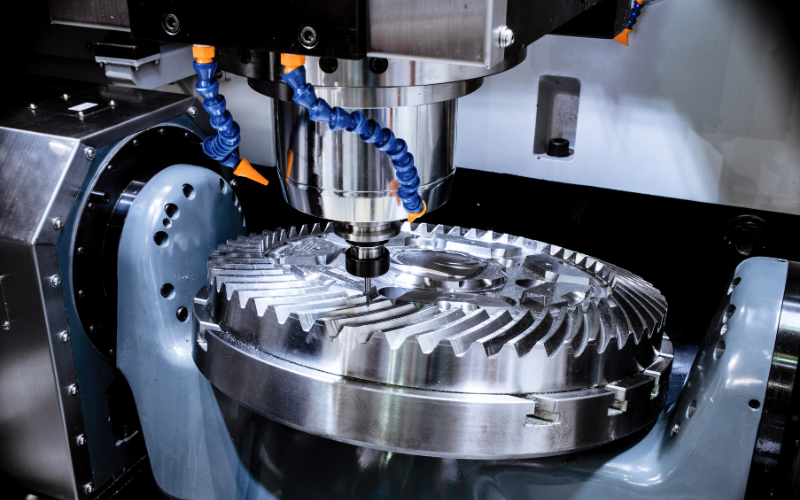

At Kreymayer, we supply state-of-the-art CNC machine tools that bring precision, efficiency, and flexibility to a variety of industries. Whether you’re in aerospace, automotive, electronics, or general manufacturing, our CNC tools are engineered to help you meet the highest standards of accuracy and productivity. Designed with cutting-edge technology and customizable configurations, our CNC machine tools offer unmatched precision, durability, and versatility for projects of any complexity.

Our Gear Racks and Pinions for CNC Machine Tools

- Precision Engineering for Superior Accuracy

Our CNC machine tools are built with high-precision components to deliver consistent, accurate cuts and shapes down to the finest detail. This level of accuracy is critical for industries that rely on intricate designs and tight tolerances, ensuring reliable and repeatable results in every operation. - Optimized for High-Volume Production

Designed to handle demanding production environments, our CNC tools deliver high-speed performance without sacrificing accuracy or quality. This allows you to boost production rates, reduce cycle times, and meet strict project deadlines, maximizing both output and profitability. - Versatile Applications Across Materials

Our CNC machines are capable of working with a wide variety of materials, from metals and alloys to plastics, composites, and ceramics. With customizable settings and tooling options, they are adaptable to both hard and soft materials, making them an ideal choice for any production need. - User-Friendly Control and Automation

With intuitive software interfaces, programmable settings, and automation features, our CNC machine tools make setup and operation easy. Automation options such as robotic loading and unloading enhance productivity while reducing the risk of errors, making your operations more efficient and consistent.

Features of Our Gear Racks for CNC Machine Tools

Precision Motion Control Systems

Our CNC machines feature advanced motion control systems for precise positioning and smooth movement, ensuring consistent quality and accuracy. This technology supports complex, multi-axis operations that are ideal for intricate designs and challenging geometries.

Powerful Spindle Options

Equipped with high-torque spindles, our CNC machine tools are optimized for demanding cutting applications, including milling, drilling, and turning. Multiple spindle options allow you to select the right configuration based on the material and complexity of your projects, enabling efficient cutting across diverse applications.

Multi-Axis Flexibility

Our CNC machines offer multi-axis capabilities that can handle complex parts with ease. From 3-axis to 5-axis configurations, these machines enable a full range of movements, allowing you to create intricate shapes and precise cuts in a single setup. This flexibility reduces setup times and enhances overall productivity.

Integrated Cooling Systems

Designed to handle intensive operations, our CNC machine tools come with integrated cooling systems to prevent overheating and ensure optimal performance. Effective cooling not only extends tool life but also helps maintain high precision during prolonged use.

Real-Time Monitoring and Diagnostics

Real-time monitoring systems provide immediate feedback on machine performance, allowing you to track production data and detect any potential issues. This feature supports predictive maintenance and minimizes unexpected downtime, helping you keep operations running smoothly.

Applications of Gear Racks and Pinions for CNC Machine Tools

1. X and Y-Axis Movement

- Linear Motion Control: In CNC machine tools, gear racks are used in the movement of the worktable or the tool holder along the X, Y, and Z axes. The rack and pinion system offers smooth and precise movement, essential for tasks like milling, drilling, turning, or engraving.

- Precision in Machining: The high precision of gear racks ensures that the CNC machine tool follows the exact path required by the programmed design. This is particularly important for intricate cuts, detailed engravings, or complex shapes, which require the tool or workpiece to move with great accuracy.

2. Tool Movement in Milling Machines

- Vertical and Horizontal Movement: In CNC milling machines, gear racks are used to move the tool or worktable along the machine’s axes. Whether cutting on the horizontal or vertical plane, gear racks ensure the tool or workpiece is positioned precisely for each cut.

- Load Handling for Milling Operations: Milling involves the application of significant force on the tool, and gear racks are capable of supporting the loads associated with such operations, ensuring smooth motion even under heavy load conditions.

3. Rotary Tables and A-Axis Movement

- Rotary Motion: Many advanced CNC machines include rotary tables or allow for movement along an A-axis (rotational axis). Gear racks are used in these rotary mechanisms to ensure smooth and precise movement, especially when performing operations like 4-axis or 5-axis machining.

- Controlling Rotation: Gear racks in the A-axis control the rotation of the workpiece or the cutting tool, ensuring that the rotation happens with high accuracy and minimal backlash. This is critical for complex cutting, turning, or drilling operations.

4. CNC Lathes

- Tool Slide and Tailstock Movement: In CNC lathes, gear racks are used to move the tool slide or the tailstock along the bed of the lathe. These components need to move smoothly and precisely along the X and Z axes for the machining process to be accurate and consistent.

- Spindle Movement and Accuracy: The gear rack system is responsible for ensuring the spindle remains in the correct position during turning operations. This is crucial for precision and achieving tight tolerances in the finished part.

5. CNC Router Machines

- Tool Head Movement: In CNC routers, gear racks are used to control the movement of the router head, ensuring it moves accurately across the X, Y, and sometimes Z axes. This movement is essential for cutting, engraving, and shaping wood, plastic, or metal materials.

- Material Handling: Gear racks also help in moving the worktable on which the material is placed. These systems allow for automatic feeding and positioning of materials for high-volume production processes.

6. Milling and Drilling Machines

- Feed Mechanism: In CNC milling and drilling machines, gear racks are used in the feed mechanisms that move the workpiece or tool in the cutting area. Accurate feed is essential to control cutting speed, depth, and material removal rate, all of which affect the final quality of the part.

- Handling Multiple Axes: In more advanced CNC machines, gear racks are employed to control multiple axes simultaneously, particularly in multi-axis milling or drilling operations, enabling the machine to execute complex movements.

7. High-Precision CNC Grinding Machines

- Grinding Wheel Adjustment: In CNC grinding machines, gear racks are used to control the precise movement of the grinding wheel along the X, Y, or Z axes. This ensures that the grinding process occurs with a high level of accuracy, particularly for producing parts with tight tolerances and smooth finishes.

- Workpiece Positioning: The positioning of the workpiece in grinding machines is critical for achieving consistent results. Gear racks provide the necessary motion for this process, ensuring that the workpiece is correctly aligned for each grinding pass.

8. Laser and Waterjet CNC Cutting Machines

- Material and Tool Positioning: In CNC laser and waterjet cutting machines, gear racks are used to move the cutting head or workpiece along the required axes. The precision of the gear rack system ensures that the material is cut exactly according to the design specifications.

- High-Speed Operation: CNC laser and waterjet cutters often operate at high speeds to cut through materials. Gear racks, due to their durability and smooth motion, are well-suited to meet the high-speed and high-precision requirements of these cutting machines.

9. CNC Plasma Cutting Machines

- Plasma Cutter Head Movement: Gear racks control the movement of the plasma cutter head along the machine’s axes. This is important for maintaining precision and ensuring that the plasma cutter head follows the exact cutting path dictated by the CNC programming.

- Accurate Cutting: With the assistance of gear racks, CNC plasma cutting machines can make intricate cuts in metal, wood, or composites with high accuracy, which is crucial for applications in aerospace, automotive, and manufacturing industries.

10. Robotic Arm Motion in CNC Applications

- Robotic Movement Control: In CNC systems that incorporate robotic arms for tasks like welding, assembly, or part handling, gear racks are used to control the movement of the arm along linear paths. This allows for precise positioning of the robotic tool or gripper to perform tasks with high accuracy.

- Load Support: Robotic arms often carry heavy loads, and the gear rack system helps ensure that these loads are moved accurately and safely without compromising the performance of the robot.

11. Tool Change Mechanisms

- Automated Tool Changer: In CNC machines, gear racks can also be part of the system that moves the automated tool changer into position. This is especially important in machines with multiple tools that need to be swapped in and out during the machining process. The precision of gear racks ensures that the tool change occurs without error.

- Reliable Motion for Tool Exchange: Gear racks ensure that the tool changer’s mechanism moves with minimal backlash and high reliability, reducing downtime and improving overall machine efficiency.

12. CNC Surface Finishing Machines

- Workpiece Adjustment: In CNC surface finishing machines, such as lapping or polishing machines, gear racks are used to adjust the position of the workpiece or tool. This precise control is necessary for achieving smooth, high-quality finishes on parts.

- Rotary Tables: Gear racks are also used in CNC surface finishing machines that incorporate rotary tables, enabling smooth and controlled rotational motion to achieve uniform surface finishes.

Customized CNC Machine Solutions for Specialized Requirements

At Kreymayer, we understand that each manufacturing operation is unique. We offer customized CNC machine solutions tailored to meet the specific demands of your applications. Whether you need a machine with a unique axis configuration, specific spindle options, or enhanced automation capabilities, our team will work closely with you to develop a customized solution that maximizes your production efficiency.

Benefits of a Custom Gear Racks for CNC Machine Tools

- Precision for Specialized Parts – Customization allows for configurations that meet exacting standards for complex, high-precision parts.

- Enhanced Workflow Efficiency – Tailored machines are optimized for your specific materials and processes, reducing setup and cycle times.

- Increased Machine Lifespan – Custom configurations reduce wear and tear, ensuring longer machine life and lower maintenance costs.

Ready to Upgrade Your Production with Gear Racks and Pinions for CNC Machine Tools

Enhance your manufacturing capabilities with advanced CNC Machine Tools from Kreymayer. Our team of experts is here to guide you in selecting the ideal machine for your applications or in creating a custom solution that meets your unique production needs. Contact us today to learn more about our CNC tools, schedule a demo, or speak with one of our specialists.

CONNECT WITH US

- Vora Industries - 91, Jawahar Industrial Estate, Kamothe Panvel 410209

- Sales: +91 7400047344

Popular Searches

Kreymayer Offers Top Quality Gear Racks and Pinions for Hydraulic Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Automotive Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Pneumatic Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Steel Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Construction Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Sheet Bending Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Oil & Gas Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Drill Machine in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Robotics in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Power Plants in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Plasma Cutting Machine in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Aerospace in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Defense in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Industrial Machinery in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Renewable Energy in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Railroad Equipment Manufacturing in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam

Kreymayer Offers Top Quality Gear Racks and Pinions for Electrical Industry in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam